Barbaros Mh. Sıra Perde Sk. No: 17/1 Üsküdar / İSTANBUL / Türkiye

X-Ray Room Lead Coating

Nuclear technology is used extensively in our daily lives in health, industry and military fields. In direct proportion to this, the number of areas that produce x-rays and the number of radiation sources are increasing day by day. The greatest effect of ionizing radiation on human health is observed as the increase in cancer cases. These radiation producing environments are licensed if they meet the conditions specified in the regulations and communiqués determined by the Nuclear Regulatory Authority.

The shielding calculations followed in the evaluation of the suitability of the architectural projects in terms of radiation safety for the buildings and radiation facilities where radiation sources will be used, manufactured or kept are made by evaluating many components. These calculations should be made by companies and engineers who are experts in their fields.

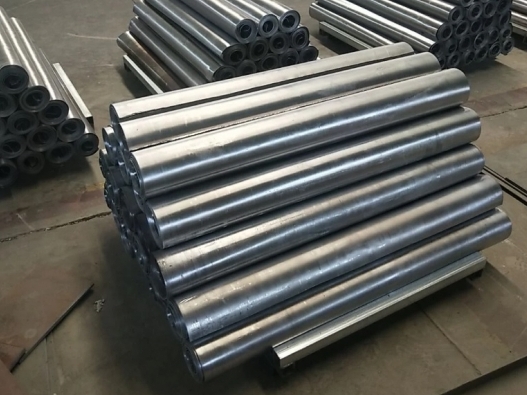

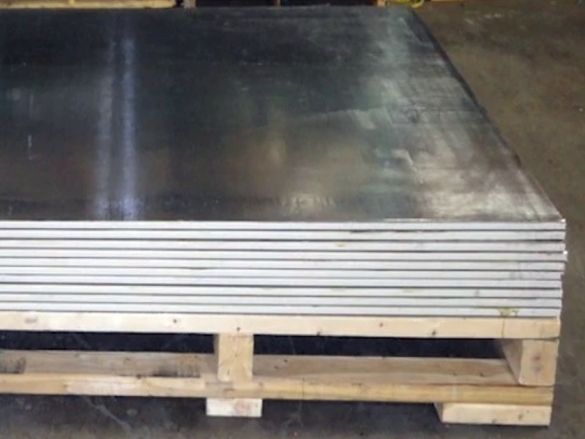

With our expert team in the field, if you have radiology and x-ray rooms, according to your existing armoring report, if your report is not available, we make the necessary shielding calculations and perform the lead coating process with the latest techniques with NDK (Nuclear Regulatory Authority) License guaranteed. Our lead sheets used in the X-ray room lead coating are 99.991% – 99.998% pure.

In radiation isolation, lead glass observation windows for personnel surveillance areas and specially produced lead armored doors for rooms are required. The amount of armoring used in the surveillance area and doors and the ratio of armor on the walls should be at the same protective level. We provide all the necessary materials for installation to distant cities and provide technical support to the smallest detail, with video and video, to the teams who will set up the room. You can contact us to get support from our expert team.

• The more armor in front of the radiation device used, the less dose is exposed.

What are the X-ray Rooms that Need to be Lead Coated?

In accordance with the provisions of the Regulation on Authorizations for Radiation Facilities and Radiation Applications, it is obligatory to obtain a license for the operation of radiation sources and radiation facilities operating in various fields and for the conduct of radiation applications. This licensing is made by NDK after physical measurement and inspection, if appropriate conditions are met. According to this regulation, it is obligatory to be shielded with lead or a material equivalent to lead shielding for radiation insulation in every place that will receive a license.

Areas that need to be armored;

Graph / Scopy Rooms

Angiography Rooms

Tomography Rooms

Mammography Rooms

Bone Density Measurement Chambers

Microfilm Rooms

Periapical , Panoramic , Dental Tomography Rooms

Spect and Pet Rooms

Industrial X-Ray Rooms

Veterinary X-Ray and Tomography Rooms etc.

For more detailed information about the service, you can browse the service page.

WHAT SHOULD BE CONSIDERED WHEN DESIGNING X-RAY ROOMS?

• Ground/entrance floors of the building should be preferred in order to make it the safest and least costly.

• It should be designed to be independent from other sections.

•Places where the density of patients and personnel are the least should be preferred.

• Areas whose lower and upper adjacent areas are not used as residential areas should always be preferred.

•Device fire, earthquake, etc. It should be installed where it can be safest against physical danger situations.

•The room size should be large enough for the radiation attendant to work comfortably and not to compromise patient comfort.

•The room should preferably have a single entrance door, and there should be no transitions from inside the room to other rooms.

•There should not be more than one device in the room, for devices with the same control unit, the room should be separated by a lead screen or a concrete wall.

• Waiting places of patients and companions should be in a separate place outside the room.

• There should be necessary radiation warning signs at the entrance door.

• The room should not be used for any purpose other than shooting.

MATTERS TO BE CONSIDERED IN X-RAY ROOM COVERING

•Lead plates to be used should have a high purity and dimensions of 1000mm x 2000mm.

• When making the armoring calculation, 2% - 3% plus overlay must be added to the account. As the width of the Lead Plates gets smaller, the wastage rates should be calculated as 4% - 6%.

•Lead plates should be coated at a height of 2 m without any gaps.

•Lead plates should overlap at least 2 – 3 cm at the joints.

•Lead plates should overlap at least 2 – 3 cm at the joints.

•Due to the lead plates placed on the doors for shielding, sagging of the door should be prevented.

•Exposed lead should not be left, it should be covered with suitable material (gypsum board, chipboard, etc.).

• Ventilation should be provided by windows or central ventilation system.

•The ventilation system should be suction from below and blow from above.

•In case there is a window; windows should be made of transom type at a height of 2 m from the floor of the room.